Pressure Vessel Steel Plate

GNEE is one experienced boiler steel plate supplier in China, our steel plate is featured with

high toughness and

low tendency, easy welding and corrosion resistant. Good properties of our product can

last for a longer time compared with other steel suppliers.

Multi-Grade Pressure Vessel Steel Plate

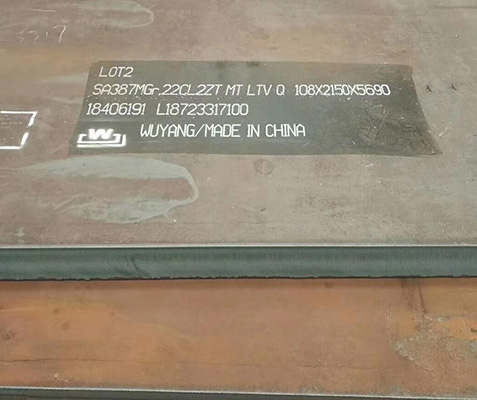

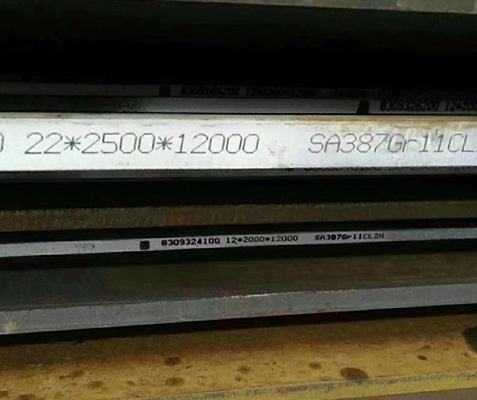

Among them, the hot grades and standard of pressure vessel steel plate include, for example, ASTM A516, ASTM A537, ASTM A516 Gr70, ASME SA537, EN10028, P355NL1, Q345R, Q245R, Q370R, 16MnDR etc. These grades are subjected to strict control specifications and technical tests, providing reliable quality and excellent performance. We can also process and cut all kinds of shaped parts according to your needs, and do transportation on behalf of customers with fast delivery time.

Pressure Vessel Steel Plate Features

1. High Strength: Boiler pressure vessel steel plates have excellent tensile and yield strength properties that allow them to withstand high internal pressures. This high strength ensures the structural integrity of the vessel under severe operating conditions.

2. Good toughness: Boiler pressure vessel steel plates exhibit good toughness, which is critical for withstanding sudden shock loads and handling thermal stresses during cyclic operations. This property helps prevent fracture and deformation of the vessel.

3. Excellent corrosion resistance: Boiler pressure vessel steel plates are usually manufactured with specific alloy compositions that provide good resistance to corrosion by various media, ensuring the life and reliability of the vessel in corrosive environments.

4. High temperature resistance: Boiler pressure vessel steel plates are designed to maintain their mechanical properties at high temperatures. They have high-temperature strength and creep resistance, enabling them to maintain structural integrity under prolonged exposure to high temperatures.

5.Weldability: Boiler pressure vessel steel plates have good weldability, enabling effective fabrication and construction of vessels that can prevent steel from cracking in welded, open, and localized stress concentration areas.

The Processes Used In The Production Of Boilers Steel Plates

1. Iron desulfurization pretreatment;

2. Smelting production of converter clean steel;

3. Off-furnace refining to remove non-metallic inclusions

4. RH cycle deep degassing process to substantially reduce the content of hydrogen, oxygen, nitrogen and other gases while ensuring stable molten steel temperature;

5. Advanced defect-free slab casting technology to obtain high quality cast slabs;

6. The use of controlled rolling and cooling process to ensure uniform organization and grain size

7. Precise heat treatment temperature control, etc.

If you want to get Pressure Vessel Steel Plate quotation as soon as possible,

please tell us the plate grade number, specific size, and quantity you need. We will contact you as soon as possible to give you the best feedback.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)