ASME Steel Plate introduction

ASME pressure vessel steel plates are typically made from carbon steel or alloy steel, depending on the specific application and operating conditions. These plates undergo stringent testing and quality control measures to ensure their mechanical properties, including tensile strength, yield strength, and impact resistance, meet the specified requirements. Gnee Group with a good relationship with China's steel production enterprises, we have fixed and flat processing, warehousing cooperative manufacturers and own logistics distribution units, which can meet the needs of customers in a timely manner.

Multi-Grade ASME Vessel Steel Plate Sale

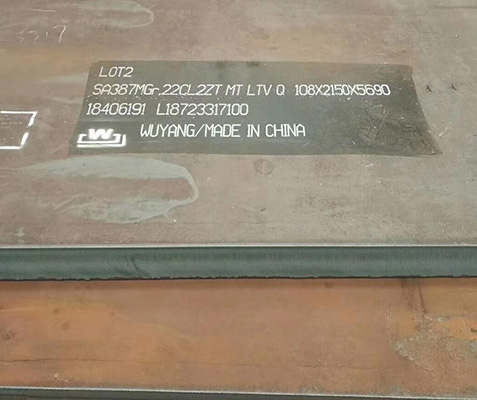

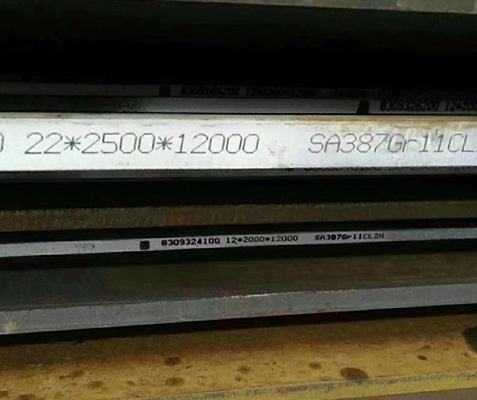

Some common grades of ASME pressure vessel steel plates include SA516 Gr55, SA516 Gr60, SA516 Gr65, SA516 Gr70, A515 Gr55, A515 Gr60, A515 Gr65, A515 Gr70, SA537CL1, SA537CL2, SA537CL3, A204, SA387 Gr11, SA387 Gr22, A285, and SA387 Gr91, among others. These grades have different chemical compositions and mechanical properties to suit various temperature and pressure ranges.

Physical Properties

| Property |

Value |

| Density |

(7.85-7.87) g/cm³ |

| Melting Point |

1420-1460 °C |

| Specific Heat Capacity |

500-540 J/kg·K |

| Thermal Conductivity |

12-14 W/m·K |

| Electrical Conductivity |

2.0-2.3 x 10^6 S/m |

Chemical Composition

| Element |

Composition Range (%) |

| Carbon |

0.08-0.20 |

| Manganese |

0.80-1.20 |

| Phosphorus |

0.035 (max) |

| Sulfur |

0.035 (max) |

| Silicon |

0.15-0.40 |

| Nickel |

0.40-0.70 |

| Chromium |

0.40-0.70 |

| Molybdenum |

0.08-0.15 |

| Copper |

0.30 (max) |

ASME Vessel Steel Plate Features

1. High Strength: ASME pressure vessel steel plates are designed to withstand high pressure and temperature conditions, providing excellent strength and structural integrity.

2. Good Weldability: ASME pressure vessel steel plates generally have good weldability, allowing for ease of fabrication and construction.

3. Excellent Toughness: This property helps prevent catastrophic failures and ensures the safety and reliability of pressure vessels.

4. Corrosion Resistance: ASME pressure vessel steel plates are often manufactured with specific alloying elements to enhance their resistance to corrosion and oxidation. This allows them to withstand corrosive environments and increases their service life.

5. Wide Range of Grades: ASME offers a wide range of pressure vessel steel plate grades to meet different application requirements. Each grade is designed to provide specific mechanical properties, chemical composition, and performance characteristics.

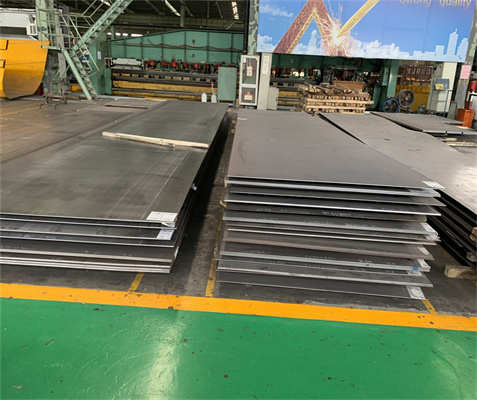

6. Strict Quality Standards: ASME pressure vessel steel plates adhere to strict quality standards and undergo rigorous testing and inspection processes. This ensures that the plates meet the necessary specifications and comply with industry standards for safety and performance.

7. Application Versatility: ASME pressure vessel steel plates find applications in various industries, including oil and gas, petrochemical, power generation, chemical processing, and more.

.jpg)

ASME Pressure vessel steel plate covers carbon steel and alloy steel grades, which are designed for use in making pressure vessels, boilers, heat exchangers and any other vessels and tanks that to store liquid or gas at high pressures. It includes applications below or similar:

1. Crude Oil Storage Tanks

2. Natural Gas Storage Tanks

3. Chemicals and Liquid Storage Tanks

4. Firewater Tanks

5. Diesel Storage Tanks

6. Gas Cylinders for Welding

7. Gas Cylinders for Cooking in peoples daily life

8. Oxygen Cylinders for Diving

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)