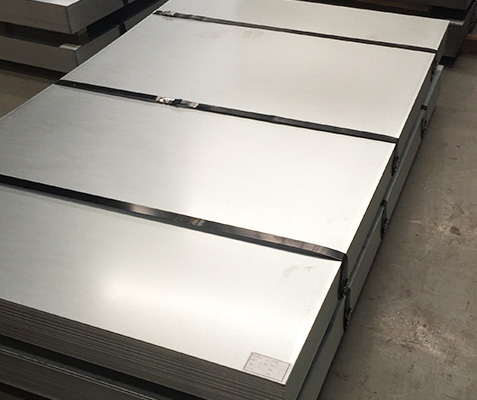

EN 10130 Cold Rolled Steel

EN 10130 standard specifies the technical delivery conditions of cold-rolled steel plates, including the requirements of dimensions, permissible deviations, surface quality, mechanical properties and processing properties of the plates. In addition to cold-rolled steel sheets of standard specifications, we also offer customized processing services, such as cutting, bending and punching according to customer requirements. In this way, customers can obtain cold-rolled steel sheets that meet specific size and shape requirements, improving production efficiency and product quality.

| Grade |

Description |

| DC01 |

Low carbon, suitable for forming |

| DC03 |

Deep drawing quality |

| DC04 |

Extra deep drawing quality |

| DC05 |

Deep drawing and aging resistance |

| DC06 |

Super deep drawing quality |

| DC07 |

Extra deep drawing and aging resistance |

EN 10130 Cold Rolled Steel Characteristics:

Excellent Surface Finish: Cold rolling process ensures a smooth and uniform surface finish on the steel, enhancing its aesthetic appeal and making it suitable for applications where appearance matters.

High Dimensional Accuracy: Cold rolling provides precise control over the thickness and dimensional tolerances of the steel, resulting in consistent and accurate dimensions. This makes it easier for manufacturers to work with and ensures better fit and assembly in various applications.

Improved Mechanical Properties: Cold rolling enhances the mechanical properties of the steel, such as strength and hardness, by introducing strain hardening and grain refinement. This improves the overall performance and durability of the material.

Good Formability: EN 10130 Cold Rolled Steel exhibits excellent formability, allowing it to be easily shaped, bent, and formed into desired configurations without sacrificing its structural integrity.

Application:

Automotive Components: Body panels, structural parts, chassis components, and automotive trim.

Appliances: Refrigerators, washing machines, dishwashers, ovens, and other household appliances.

Construction: Roofing, wall panels, structural members, interior fittings, and architectural elements.

Furniture: Cabinets, drawers, shelves, frames, and other furniture components.

Electric/Electronic Equipment: Electrical enclosures, cabinets, computer cases, electronic components, and housings.

Pipes and Tubes: Manufacturing of pipes and tubes for various industries.

Stamped Parts: Stamped and formed components for various applications.

Brackets and Supports: Supporting brackets and components for machinery and equipment.

HVAC Systems: Heating, ventilation, and air conditioning systems and components.

General Engineering: Various engineering applications requiring precision, formability, and surface finish.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)