Hot dip galvanizing and boronizing are two distinct processes used to coat a base metal or alloy to significantly enhance its durability. Both methods form a protective surface layer on the chosen base metal, but each process is fundamentally different. Let's delve deeper into each process to understand their differences.

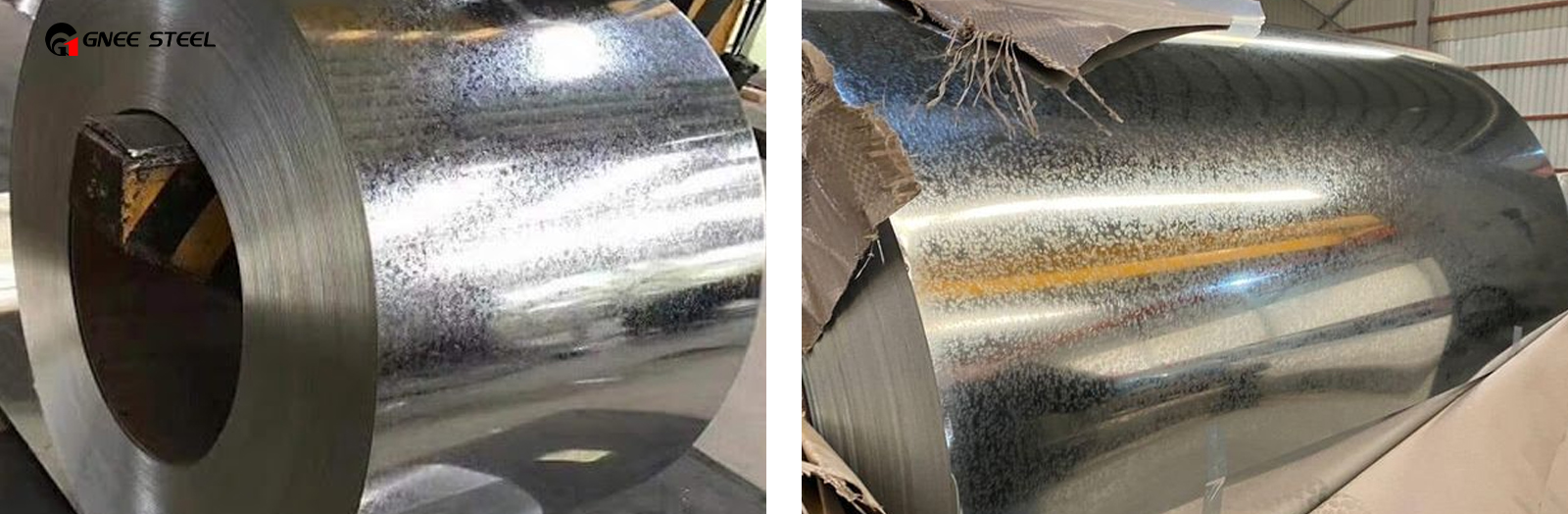

Hot Dip Galvanizing

Hot dip galvanizing involves immersing the base metal, usually steel, into a bath of molten zinc at high temperatures, approximately 450 degrees Celsius (840 degrees Fahrenheit). The steps involved in this process include:

Cleaning: The base metal is first cleaned in a caustic solution to remove dirt and then passed through an acidic solution to eliminate iron oxide flakes.

Chemical Cleaning: Further cleaning is done using a chemical agent like ammonium chloride to enhance the bonding of zinc to the base metal.

Dipping: The cleaned base metal is dipped into the molten zinc, forming a protective zinc coating.

Boronizing

Boronizing is a surface hardening process for steel that involves the addition of boron to the base metal. This thermochemical process diffuses boron atoms into the surface of the base metal.

Key aspects of boronizing include:

Surface Hardening: It specifically hardens the surface of the base metal, providing enhanced durability.

Boron Diffusion: Boron atoms penetrate the surface, creating a hard and wear-resistant layer.

Differences in Functionality

Understanding the functional differences between hot dip galvanizing and boronizing helps in choosing the appropriate method for specific applications:

Corrosion Resistance:

Hot Dip Galvanizing: Primarily improves the corrosion resistance of steel or other base metals. The zinc coating acts as a barrier to protect the metal from environmental factors.

Boronizing: Provides even higher corrosion resistance by creating a hard boron-infused layer on the surface, which is more resistant to wear and tear.

Wear Resistance:

Hot Dip Galvanizing: Enhances corrosion resistance but does not significantly improve the wear resistance of the base metal.

Boronizing: Significantly reduces wear and tear, making the base metal highly durable and capable of withstanding external elements without compromising functionality.

Mechanical Properties:

Hot Dip Galvanizing: Focuses on corrosion resistance without substantial changes to the mechanical properties of the base metal.

Boronizing: Improves not only wear resistance and corrosion resistance but also enhances the temperature stability and several other mechanical properties of the base metal.

Why choose GNEE hot-dip galvanizing or boronizing services?

If you are looking forward to high-quality hot-dip galvanizing or boronizing services, come to GNEE STEEL. With years of experience and professional knowledge in this field, GNEE STEAL has become one of the top service providers in this field. Therefore, for various galvanizing or boronization requirements, what users need to do is to contact GNEE STEEL's experts and professional teams to obtain the best solution.

Contact us now!