Measures to improve work rate in bar rolling

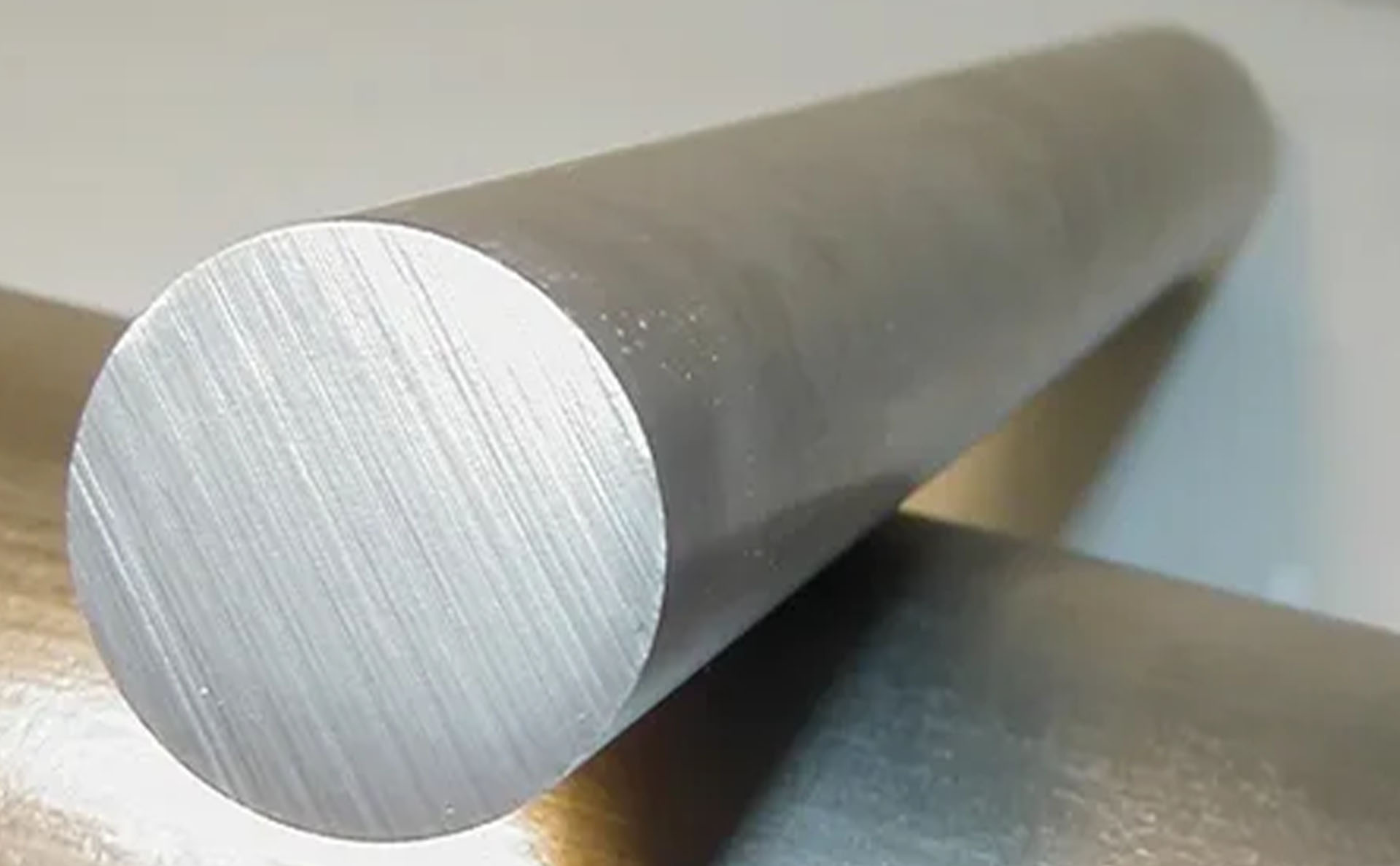

Improving product quality, increasing productivity and reducing downtime are consistent requirements in today's highly competitive bar market. To meet these requirements, it is necessary to improve the operation rate in the bar rolling, reduce production costs. Specifically from the reduction of rolling faults, improve mill utilization, improve product dimensional tolerances and other aspects of manpower.

1. Improve the utilization rate of the mill measures

Improve the utilization rate of the mill, reduce the replacement of rolling grooves, roll time, the newly developed non-standard rolling of the new rolling program to reduce downtime, and improve the utilization rate of the mill. Through the composite processing of finishing mill stand rolls, can be used in the production of adjacent varieties of the same specifications channel, so that when replacing the specifications and varieties, the operation of the roll change is relatively flexible and easy to reduce the time to change slots, change rolls.

2. Product size tolerance control measures

Negative tolerance rolling is a technology commonly used in bar production line, the negative tolerance rate must be increased within the allowable deviation of the national standard, and at the same time, according to the production of the actual development of appropriate measures to improve the negative tolerance rate can be realized. Negative tolerance rolling not only saves metal to improve the effective utilization of steel, but also bring considerable economic benefits to the enterprise.

①Reasonable control of heating temperature and rolling cooling temperature

Billet heating temperature has a certain impact on negative tolerance rolling, mainly in the heating temperature is too high, the internal organization of the billet austenite grain growth. Control of billet heating temperature, reduce the rolling temperature to achieve grain refinement, is to enhance the performance of steel bar effective measures, large bar line operation area through reasonable control of the heating temperature, will be 1 rack outlet temperature control between 1000 ~ 1,050 ℃, control the growth of austenite grains, which not only reduces the heating fuel consumption, but also for the negative tolerance rolling to create the conditions. Control the final rolling temperature, make full use of the cooling device to improve steel properties, according to different specifications to adjust the cooling device water pressure in each section, a reasonable distribution of open water nozzle, increase the cooling strength of the steel bar, so that the internal organization of the steel bar to further refinement, the performance is also improved, the negative tolerance rate will also be improved.

② Optimize the design of the finished hole size

The geometry of the section of the steel bar is the most direct cause of negative tolerance, reasonable design of the hole is to improve the level of negative tolerance rolling effective means. According to the national standard of hot-rolled ribbed steel bar and the technical quality requirements of JISCO, combined with the process layout and operation level of the big bar line, the hole pattern can be designed in accordance with the internal control standard of the maximum negative tolerance rate. Negative tolerance rolling is a demanding process, under the premise of all measures, the staff operating skills on the negative tolerance rate also has a certain impact, therefore, in grasping all the work at the same time, focusing on the staff operating level, in order to make the level of negative tolerance control is guaranteed.