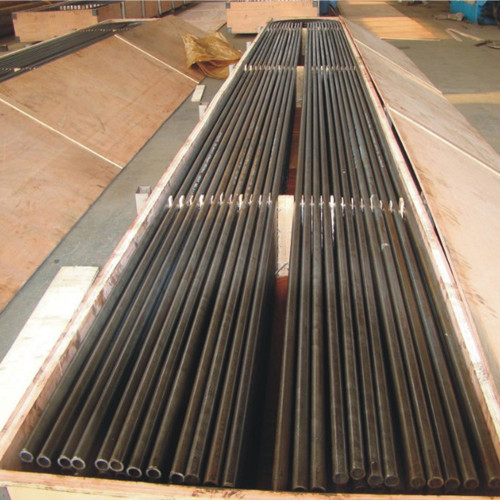

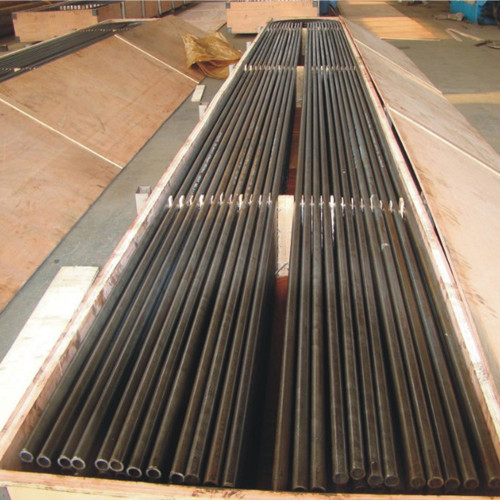

Product introduction

ASME SA192 Seamless boiler Pipe pro commutatione caloris Specification

Hic dux normas specificationum pro minimo parietis crassitudine tegit, inconsutilem carbonis bullientem et superheatri fistulas pro servitio summus pressurae. Ferrum accommodatam compositioni chemica chemicae componet carbonis, manganesi, phosphori, sulphuris et pii. Tubuli numerum duritiem valorem specificum non excedentes habebunt. Probationes mechanicae sequentes agendae sunt, nempe: adulatione probatio; flagrare test; duritiem probare; et hydrostatica test.

1. Haec specificatio minimum crassitudinem parietis operit, inconsutilem carbonis bullientis et superheatri fistulae ad ministerium altum pressurae.

2.SA192 Tubae boilis magnitudines et crassitudines huic specificationi plerumque praestandae sunt 1/2 ad. ad 7 in. [12.7 ad 177.8 mm] extra diametrum et 0.085 ad 1.000 in. [2.2 ad 25.4 mm], inclusive, in minimum. murum crassitudine. Tubingae aliae dimensiones habentes praestari possunt, dummodo huiusmodi fistulae omnibus aliis requisitis huius specificationis pareant.

3.Mechanica proprietas requisita ad Tubingam minorem quam 1/8 non applicat. [3.2 mm] intra diametrum vel 0.015 in.

| A192 Tubuli Specification |

ASTM A192 / ASME SA192 |

| A192 Tubuli Grades |

A192 Grade Tubuli et Tubingae |

| A192 Tubuli Type |

Seamless - Hot Rolled / Frigus Drawn |

| A192 Tubuli externae Diameter Location |

1/4" NB Ad 2" NB (Nominal Bore Size) |

| A192 Tubuli Wall Crassitudo |

1 mm Crassitudo ad 8 mm |

| A192 Tubuli Longitudo |

5800mm; 6000mm; 6096mm; 7315mm; 11800mm; et sic porro. Max longitudo: 27000mm, etiam U flexio offerri potest.

|

| A192 Tubuli desinit |

Patet Fines / Beveled Ends / |

| A192 Tubuli Delivery Conditions |

Sicut Rolled, frigida tracta, normalizing Rolled |

| A192 Tubuli Coating |

Epoxy Coating / Color Pain Coating / 3LPE Coating. |

| A192 Tubuli Alia Testis |

NACE MR0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, SWC, H2 SERVITIUM, IBR, PWHT etc. |

| A192 Tubuli Dimension |

Omnia fistulae fabricata et inspecta sunt probata signis congruentibus inclusis ASTM, ASME, API. |

Dimensio Muri Crassitudo tolerantiae (SA-450/SA-450M);

|

OD In (mm)

|

+

|

-

|

WT In(mm)

|

+

|

-

|

|

< 1(25.4)

|

0.10

|

0.10

|

≤ 1.1/2(38.1)

|

20%

|

0

|

|

1 ad 1.1/2(25.4 to38.1)

|

0.15

|

0.15

|

> 1.1/2(38.1)

|

22%

|

0

|

|

> 1.1/2 ad<2(38.1 ad 50.8)

|

0.20

|

0.20

|

|

|

|

|

2 ad <2.1/2(50.8to 63.5)

|

0.25

|

0.25

|

|

|

|

|

2.1 ad < 3(63.5to 76.2)

|

0.30

|

0.30

|

|

|

|

|

3 ad 4 (76.2 ad 101.6)

|

0.38

|

0.38

|

|

|

|

|

> 4 ad 7.1/2(101.6to 190.5)

|

0.38

|

0.64

|

|

|

|

|

> 7.1 ad 9 (190.5to 228.6)

|

0.38

|

1.14

|

|

|

|

Duritia:

|

Brinell HardnessNumber

(WT≥) 0.200In ( 5.1mm )

|

Rockwell HardnessNumber

(WT≥) 0.200In(5.1mm )

|

|

137HRB

|

77HRB

|

English

English  Russian

Russian  Albanian

Albanian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Hmong

Hmong  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew  Icelandic

Icelandic