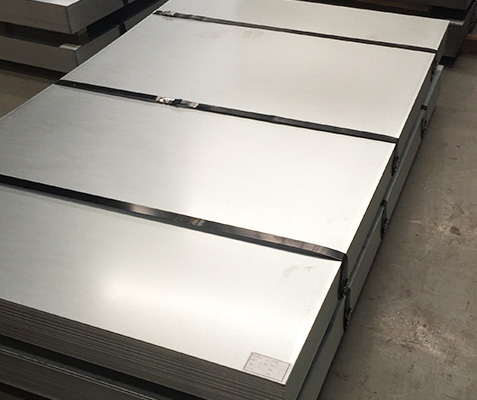

ST12 steel ntawv

ST12 txias dov hlau yog qhov tseem ceeb kub dov hlau uas tau ua tiav lawm. Thaum kub dov hlau tau txias, nws yog dov mus rau qhov ua tau zoo dua qhov ntev thiab zoo dua qhov zoo.

Cov ntawv txias txias (CR steel ntawv) yog qhov tseem ceeb kub dov hlau uas tau ua tiav ntxiv

Txias 'rolled' steel phaj feem ntau yog siv los piav txog ntau yam ntawm cov txheej txheem tiav - txawm li cas los xij, 'txias dov' tsuas yog siv rau cov nplooj ntawv uas tau txais kev sib tw ntawm cov menyuam. Tej yam xws li tuav lossis cov raj yog 'kos,' tsis dov. Lwm cov txheej txheem txias txias muaj xws li tig, sib tsoo thiab polishing-txhua qhov uas yog siv los hloov cov khoom kub uas twb muaj lawm rau hauv cov khoom ua kom zoo dua qub.

ST12 txias dov steel kauj feem ntau tuaj yeem txheeb xyuas los ntawm cov yam ntxwv hauv qab no:

1.Cold rolled steel tau zoo dua, ntau qhov chaw tiav nrog kev ua siab ntev dua

2.Smooth nto uas feem ntau oily rau kov hauv CR steel ntawv

3.Bars muaj tseeb thiab square, thiab feem ntau muaj cov npoo thiab cov ces kaum zoo

4.Tubes muaj zoo concentric uniformity thiab straightness, ua los ntawm txias dov khoom.

5.Cold rolled steel coil nrog cov yam ntxwv zoo dua li cov hlau dov kub, nws tsis yog qhov xav tsis thoob tias cov hlau txias txias feem ntau yog siv rau kev siv ntau dua los yog qhov tseem ceeb ntawm kev zoo nkauj. Tab sis, vim yog cov txheej txheem ntxiv rau cov khoom txias tiav, lawv tuaj ntawm tus nqi siab dua.

Nyob rau hauv cov nqe lus ntawm lawv lub cev yam ntxwv, txias ua hauj lwm steels yog feem ntau nyuaj thiab muaj zog dua li cov qauv kub dov steels. Qhov no yog vim qhov txias-kuav los tiag steel ua tiav qhov tseem ceeb tsim cov khoom ua haujlwm tawv. Nws tsim nyog sau cia tias cov kev kho mob ntxiv no tuaj yeem tsim kev ntxhov siab sab hauv hauv cov khoom siv. Nyob rau hauv lwm yam lus, thaum fabricating txias-ua hauj lwm steel-txawm txiav, sib tsoo los yog vuam nws-qhov no yuav tso tawm tensions thiab ua rau unpredictable warping.

English

English  Russian

Russian  Albanian

Albanian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latin

Latin  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew  Icelandic

Icelandic

.jpg)